Corn growers across Ohio are all too familiar with the threat of vomitoxin—also known as VOM or DON—and the deva station it can cause at harvest. Grain producers who haven’t been affected are the lucky ones, as a majority of Ohio’s farms have dealt with infection. For those who have, the impacts are real: docked grain prices, rejected loads, contaminated bins, and even denied crop insurance claims. And often, growers are left with a lot of unanswered questions.

That’s why the Ohio Corn Checkoff (OCMP) decided to take action. Through ongoing investments in research at the Ohio State University, we’re working to better understand vomitoxin—how to predict it, how to prevent it, and what to do if it shows up in your crop.

While there’s currently no cure for the fungus that causes vomitoxin, we’ve made significant progress in finding strategies to reduce the risk. This page aims to share those insights, answer your most common questions, and provide practical tools to protect your crop and your bottom line. Consult your certified crop advisor or agronomist for advice on your specific fields.

A new vomitoxin crop risk prediction tool has been developed to help corn producers evaluate their risk of infection on a field-by-field basis. The tool uses detailed weather data, like temperature, humidity, and rainfall, both current and past, and your planting date to calculate your risk of infection. It looks at hourly weather forecasts and calculates factors such as daily weather patterns, growing degree days, and the likelihood of disease. This allows farmers to see if their fields might be at risk for vomitoxin based on local weather conditions, so they can take steps to protect their crops.

What is Vomitoxin?

Vomitoxin, or DON for short, is a toxin produced by a fungus called Fusarium Graminearum that infects corn and other grains. This fungus thrives in warm, wet weather—especially during silking, and can cause serious problems during harvest.

Vomitoxin usually doesn’t harm people in small amounts, but it’s a major concern for feeding livestock. Animals like pigs, chickens, and young cattle can get sick from eating contaminated grain with vomitoxin. It can cause them to eat less, grow slower, and develop health problems, which makes feed mills and buyers very cautious about what they accept. Livestock feed accounts for about 1/3 of Ohio’s corn demand, making it a vital part of Ohio’s agricultural economy.

Listen to our Kernels podcast episode to learn more about what vomitoxin is, and the advances that have been made in mitigating it.

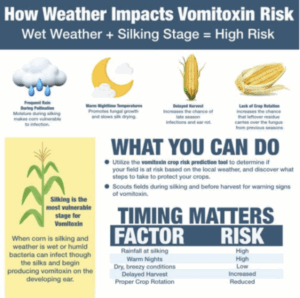

How Weather Increases Risk

Vomitoxin is more likely to show up when the weather is warm and wet, especially during the silking stage of corn growth. That’s when the plant is most open to infection from the fungus that causes vomitoxin.

Understanding how these factors raise infection risk can assist farmers in making timely management decisions, preventing declines in quality and prices.

Use this checklist to help evaluate vomitoxin risk during silking:

- Monitor local weather forecasts

- Scout daily during flowering

- Note hybrid susceptibility

- Document any ear damage (insects or weather)

- Consider a timely fungicide if warranted

- Plan for early harvest if conditions allow

How Vomitoxin Affects the Price at the Elevator

Grain buyers like elevators, ethanol plants, and feed mills test for vomitoxin and may dock your price or even reject your corn if levels are too high.

- 2.0 ppm or higher – You’ll probably notice discounts on prices or restrictions on the amount that can be mixed with cleaner grain.

- 5.0 ppm and above – Corn at this level is usually discarded for food or feed purposes. That’s because the FDA restricts vomitoxin to 1 ppm for food and 5 ppmfor specific animal feeds.

- Severely contaminated loads – These may be down graded and sent to ethanol plants instead, usually for a lower price. But vomitoxin doesn’t disappear during ethanol production—it can concentrate in DDGs, affecting their value as feed.

Even small amounts of vomitoxin can cut your corn’s value by 10% or more, so catching and managing it early is key to protecting your bottom line.

What We’re Learning

Checkoff-supported research helps farmers better understand the disease at all stages—pathogen, host, and environment—and how to reduce its impact.

From hybrid selection and fungicide timing to harvest strategies, new data is helping farmers make more informed decisions every year.

Together, we’re helping growers reduce risk, protect quality, and maintain profitability.

- Toxin-resistant hybrids: Evaluating performance under varying weather conditions.

- Fungicide studies: Pinpointing optimal timing and products for disease control.

- Post-harvest solutions: Exploring grain drying, storage, and mitigation techniques.

- Collaboration with OSU Extension: Translating field research into real-world tools for farmers.

What you need to know about cleaning and storing contaminated corn

There are a few steps you can take during harvest to mitigate the impact on your paycheck at the elevator.

- Adjust your combine settings to chop up the fines as much as possible to promote decomposition, which takes away the host environment for the fungus. Harvest sooner rather than later to give the mold less time to grow.

- To prevent vomitoxin from worsening after harvest, dry your grain below 15% moisture and store it in cool, clean bins.

- Regularly check for mold, insects, and temperature.

Note: drying or cooling won’t remove existing vomitoxin, but these steps help prevent it from spreading.

Grain cleaning may reduce vomitoxin in corn, but it hasn’t been fully tested with farme quipment. Researchers are testing three types of cleaners, from basic to advanced models, using screens and air for better cleaning. We’ll keep you updated on this research as it develops.

Fungicide Application

Fungicides can be used to manage corn diseases, but timing is critical to effectiveness. Fungicide products need to be applied when corn silks are still green and wet(early to mid-silking). If you wait until the silks are dry and brown, the fungicide won’t work as well.

Because it’s important for the spray to reach deep into the canopy and fully cover the silks, researchers are also testing different ways to apply fungicides, including drones, grounds prayers, and aerial methods.

Bottom line, here’s what Ohio farmers need to do:

- Use the Crop Risk Prediction Tool to calculate your risk.

- Determine if that risk is high enough to warrant mitigation measures like fungicide.

- Talk to your agronomist to determine what your individual fields need.

Together, We’re Making Progress

Dealing with vomitoxin can be challenging, but improved tools, research, and proactive strategies are helping Ohio corn growers to minimize risks and safe guard their crops.